Drill File CAM Configuration

Our service cannot process Altium’s Drill Drawing (DD1) or Drill Guide (GG1) files. We need the drill file to be in NC Drills format file. Altium typically generates these with a .TXT extension.

Altium has published a guide on producing those files here: http://wiki.altium.com/display/ADOH/NC+Drill+Output+Options

The drill format options we use are as follows:

-

We prefer a 2:4 format when using Inches, or a 3:3 when using Millimeters. Some versions of Altium do not have these options, so you should use 3:4 in Inches, or 4:4 in Metric, and verify that the drill hits align correctly on the previews.

-

Check

Keep Leading And Trailing Zeroes -

Generate Seperate NC Drill filesmay be checked or unchecked. We will merge drill files automatically. -

Use Drilled Slot Commandmay be checked if you wish to include in your design. See our slots page for noted restrictions on using drill slots. -

Uncheck

Generate Board Edge Route Paths. We do not use provided edge-milling paths, and including them may have unexpected results if they’re used for manufacturing. -

For

Coordinate Positions”, you’ll typically checkReference to Absolute Origin. However, since this option needs to align with a similar CAM setting for the gerber files, consider changing it toReference to Relative Originif your gerbers appear incorrect in our previews. -

Optimize Change Location Commandsdoesn’t matter, as we will recalculate drill movement.

In some cases, including the binary .DRL file will cause us to reject the board even if you have a .TXT file in NC Drill format. Deleting the .DRL file will resolve that issue.

Example

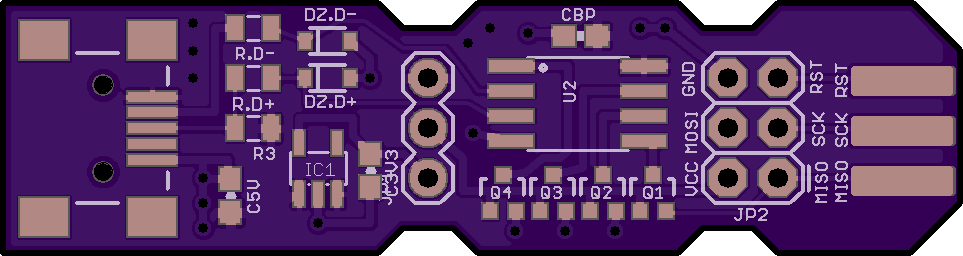

The following image shows a properly aligned drill file, and should resemble your previews when uploading your board. If anything looks strange, consult our Drill Troubleshooting Guide for some tips or email [email protected] for assistance.