2 Layer Super Swift Service

Need 2-layer boards in a hurry? Our Super Swift Service has the same quality you know and love, with an even faster turn time of 5 business days.

Pricing

$10 per square inch, which includes three copies of your design.

For example, a 2 square inch board would cost $20 and you’d get three copies of your board. This includes our Free Shipping option, although expedited shipping options are available.

Turn Times

Orders are sent to fabrication daily and are guaranteed to ship within 5 business days. 90% of our super swift orders ship within 4 business days.

Orders placed before 11AM on Monday will always ship by Friday of that week.

Orders placed before 11AM on Tuesday will typically ship by Friday, but may ship the following Monday.

You can get a quote, approve a design, and pay for an order at OSH Park.

Super Swift Service is not available for Medium Run or Four Layer orders.

Note for international orders: In many cases, it will cost less and arrive faster if you order on the standard 2 layer service with expedited shipping.

Common Specs

These specs apply to all our PCB services.

| Spec | Value | |

|---|---|---|

| Manufactured in the United States | Yes | |

| Lead Free compatible | Yes | |

| RoHS Compliant | Yes | |

| High Temp | Yes, 175 Tg or higher (see Material Specs) | |

| PCB Finish | ENIG (Gold), compliant with IPC-4552 | |

| Soldermask Type | SMOBC (Soldermask Over Bare Copper), both sides | |

| Silkscreen Type | High Res DLP, both sides |

Stackup

| Thickness | Layer | Tolerance |

|---|---|---|

| 0.6 mil (0.0152mm) | silkscreen | +/-0.2mil (0.00508mm) |

| 0.6 mil (0.0152mm) | solder resist | +/-0.2mil (0.00508mm) |

| 1.4 mil (0.0356mm) | 1 oz copper | |

| 60 mil (1.5240mm) | core | +/-6mil (0.1524mm) |

| 1.4 mil (0.0356mm) | 1 oz copper | |

| 0.6 mil (0.0152mm) | solder resist | +/-0.2mil (0.00508mm) |

| 0.6 mil (0.0152mm) | silkscreen | +/-0.2mil (0.00508mm) |

Material Specs

| Spec | Value | |

|---|---|---|

| Substrate | 175Tg FR4 | Kingboard KB6167F Datasheet |

| Board Thickness | 63mil (1.6mm) nominal | |

| Dielectric | 4.5 at 10Mhz | |

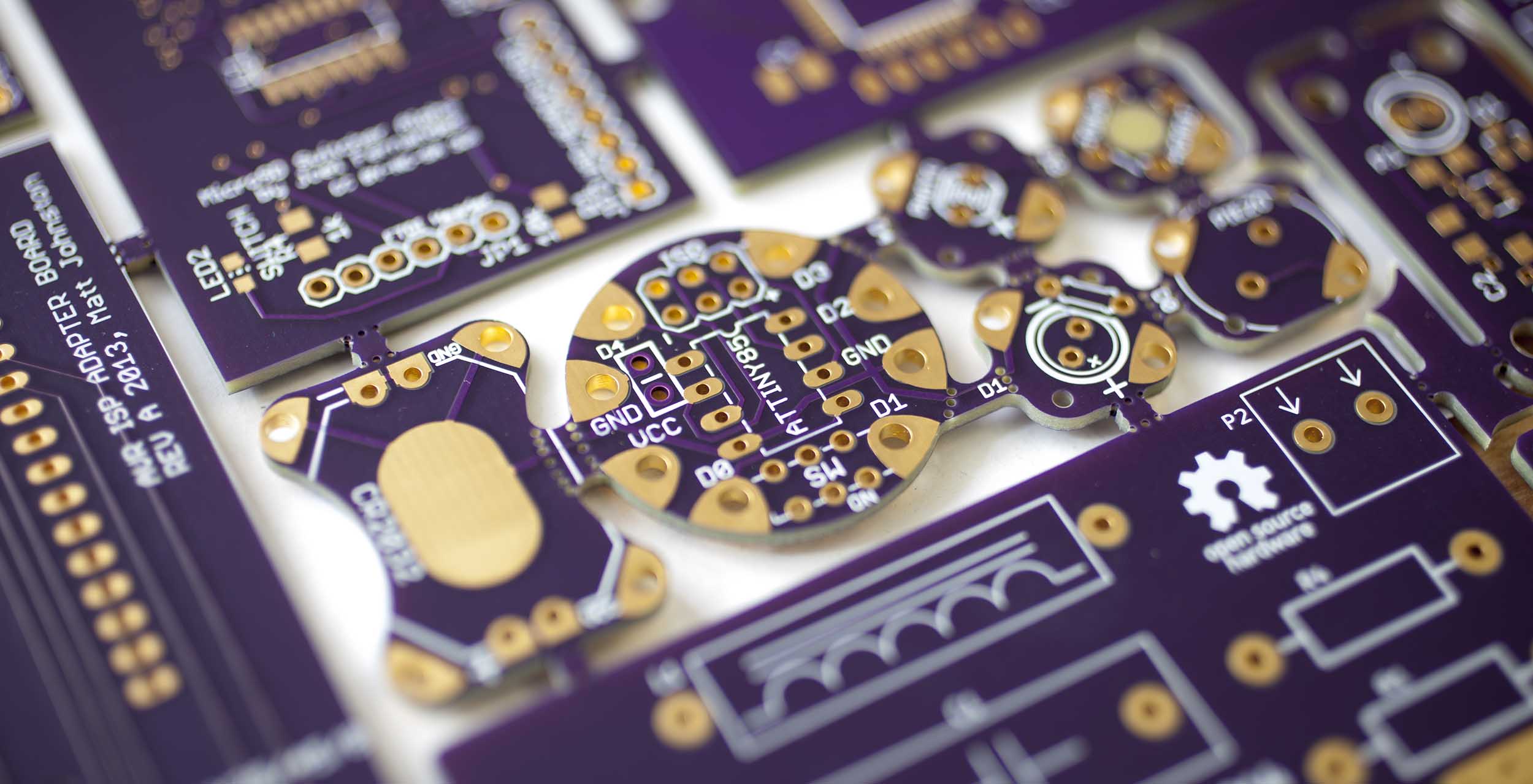

| Soldermask Color | Purple | Mask Datasheet |

| Minimum soldermask web | 4 mil (0.1016mm) | |

| Maximum soldermask alignment | 3mil (0.0762mm) | Covers retraction, expansion, and shift |

| Silkscreen minimum line width | 5 mil (0.127mm) (recommended minimum) 3 mil (0.0762mm) (short lines, text, graphics) |

Silkscreen Datasheet |

| Maximum board size | 16in (406.4mm) by 22in (558.8mm) | |

| Minimum board size | 0.25in (6.35mm) by 0.25in (6.35mm) |

Copper Specifications

| Spec | Value | |

|---|---|---|

| Copper Layers | 2 | |

| Copper Weight | 1oz | |

| Trace Spacing | 6mil (0.1524mm) | |

| Trace Width | 6mil (0.1524mm) | |

| Annular Ring | 5mil (0.127mm) | |

| Board Edge Keepout | 15mil (0.381) from nominal board edge | |

| Via Plating Thickness | 1mil (0.0254mm) |

Drill Specifications

| Spec | Value | |

|---|---|---|

| Minimum Annular Ring | 5mil (0.127mm) | |

| Minumum Drill Size | 10mil (0.254mm) | |

| Minimum Slot Size | 20mil (0.508mm) (drill slot only) | Additional information on slots |

| Drill Size tolerance | Max: +/- 2.5mil (0.0635mm) Typical: +/- 1.0mil (0.0254) |

|

| Drill Positional Tolerance | Max: 2mil (0.0508mm) Typical: <1mil (0.0254mm) |

|

| Via Tenting | Yes (filled hole and flat surface not guaranteed) | |

| Buried Via | No | |

| Blind Via | No | |

| Filled+Plated Vias (via-in-pad) | No | |

| Overlapping drills | Allowed, but not guaranteed. May result in missing or slotted holes. 5 mil (0.127mm) clearance is recommended between holes. |

|

| Castellations | Allowed, but not guaranteed | Details and recommendations |

| Maximum Drill Size | None | Drill sizes above 250mil (6.35mm) will be fabbed, but with larger milling tolerances. |