Drill Specs

Specs

2 Layer Services

| Spec Type | Note | |

|---|---|---|

| Minimum Hole size | 10 mil (0.254mm) | Holes belows this size will be rounded up |

| Maximum Drilled Hole Size | 260 mil (6.604mm) | Holes exceeding this size will be milled |

| Annular Ring | 5 mil (0.127mm) | |

| Via Plating Thickness | 1 mil (0.0254mm) | |

| Fabricated Hole Size Tolerance | +/-2.5mil max (0.0635mm) | +/-1 mil typical (0.0254mm) |

| Fabricated Hole Position Tolerance | +/-2.5mil max (0.0635mm) | +/-1 mil typical (0.0254mm) |

For 2 layer boards, the smallest drill size is 10 mil (0.254mm), with a 5 mil (0.127mm) annular ring.

4 Layer Services

| Spec Type | Note | |

|---|---|---|

| Minimum Hole size | 10 mil (0.254mm) | Holes belows this size will be rounded up |

| Maximum Drilled Hole Size | 260 mil (6.604mm) | Holes exceeding this size will be milled |

| Annular Ring | 4 mil (0.1016mm) | |

| Via Plating Thickness | 1 mil (0.0254mm) | |

| Fabricated Hole Size Tolerance | +/-2.5mil max (0.0635mm) | +/-1 mil typical (0.0254mm) |

| Fabricated Hole Position Tolerance | +/-2.5mil max (0.0635mm) | +/-1 mil typical (0.0254mm) |

For 4 layer boards, the smallest drill size is 10 mil (0.254mm), with a 4 mil (0.1016mm) annular ring.

6 Layer Services

| Spec Type | Note | |

|---|---|---|

| Minimum Hole size | 8 mil (0.2032mm) | Holes belows this size will be rounded up |

| Maximum Drilled Hole Size | 260 mil (6.604mm) | Holes exceeding this size will be milled |

| Annular Ring | 4 mil (0.1016mm) | |

| Via Plating Thickness | 1 mil (0.0254mm) | |

| Fabricated Hole Size Tolerance | +/-2.5mil max (0.0635mm) | +/-1 mil typical (0.0254mm) |

| Fabricated Hole Position Tolerance | +/-2.5mil max (0.0635mm) | +/-1 mil typical (0.0254mm) |

For 6 layer boards, the smallest drill size is 8 mil (0.2032mm), with a 4 mil (0.1016mm) annular ring.

FAQ

What happens if I violate the minimum drill size?

The drill will be increased to the minimum for that service. In effect, this simply reduces the size of your annular ring.

What happens if I exceed the maximum drill size?

Instead of being a “drilled” hole using the specifications here, it will be automatically converted to a “milled” hole.

In this case, the plating, position, and size will remain as indicated in the original file. However, the fabrication tolerances are changed in a slight, but not typically signification fashion.

What happens if I violate the annular ring spec?

Generally nothing too bad, but it should be avoided whenever possible.

The annular ring spec accounts for worst-case fabrication tolerances. Since our typical tolerances are below that, the annular ring usually can decrease by 1 mil (0.0254mm) without serious issues. However, issues that do occur from annular ring violations can be very inconsistent and difficult to debug.

How do hole sizes tolerances work?

All plated holes have a slight size tolerance to them, so the hole on the PCB will always be close to, but not exactly, the size specified.

If you’re following manufacturer guidelines for a part, you generally won’t notice. Many manufacturer datasheets expect a PCB manufacturing tolerance of +/-3 mil. Since our process is more precise than this expectation, the fabricated PCB will always meet manufacturer expectations.

If your hole size is nearly identical to the component pin size, you may encounter component fit issues when the fabricated hole size is below the indicated size. In these cases, the effective functionality of the board is dependent on the manufacturing tolerance, with some orders working as expected, and others containing fit issues.

When in doubt, check the manufacturer guidelines, and adjust the footprint as needed to ensure that the smallest possible hole size will still work correctly with your component.

What file format do I use?

We require the drills to be indicated using the Excellon Drill format.

While most tools can generate this file, not all design tools comply with the format standard by default. Our Design Tool Help pages will help configure most tools to generate this correctly.

If your tool is not listed, configure the drill file output to use the following:

- Units:

INCHES - Format or Precision:

2:4(sometimes shown as Digits:4) - Zero Suppression:

NoneorLeading. - Coordinate Origin should be left as default (usually

Absolute) unless the drills are offset from the board.

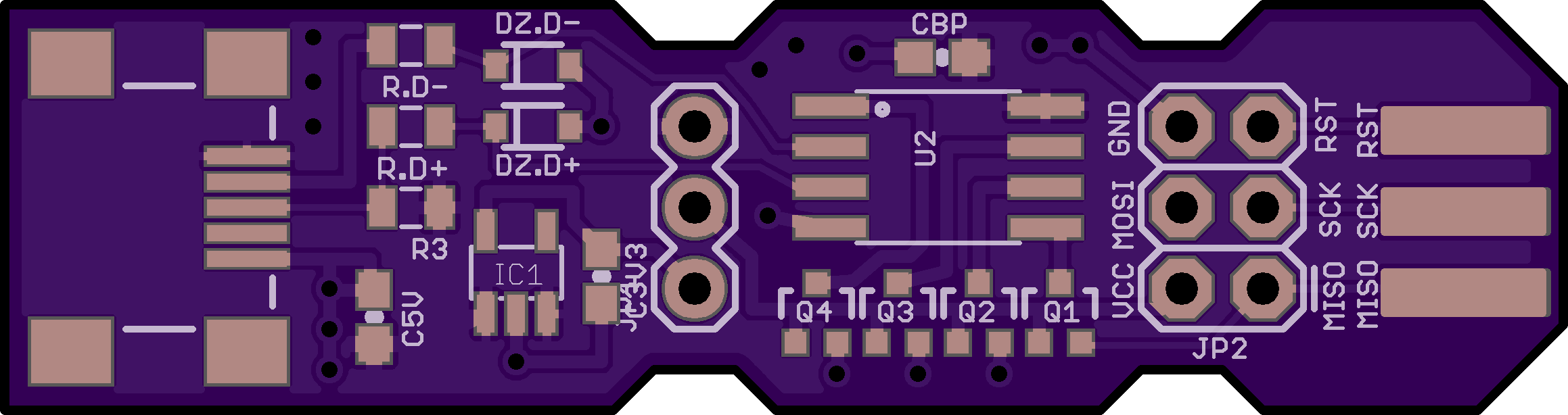

If we understood your file format correctly, you’ll see a board preview similar to this one.

What happens when my file format is wrong?

It somewhat depends on the tool and the format difference. Some tools provide information that ensures we can read it correctly.

In some cases, the drill file will result in an upload failure.

In all other cases, our previews will show you how we interpret the drill files. If something looks incorrect, you’ll want to correct your file.

If you proceed with an incorrect order, our system will typically flag your order, and we’ll notify you or make adjustments automatically. However, we cannot guarantee this.

In a worst-case scenario, your board may be fabricated in an unusable state, but exactly as indicated in the previews.

Why do the previews not show my slots?

Drill slots added by the design tool will be shown on your previews as expected. However, certain tools cannot generate drill slots, or do so in ways that are not fully supported by our process. See our Slots page for more information on how to validate slots.